- gurudevcontainers@gmail.com

- +91-9879080121/9825428486

- Palanpur- 385001. Gujarat - India.

Our Products

Triple Seam Tight-Head Steel Drums IS 1783 (Part 2) – 1988 Type 2

Reinforced Spiral Seam Drums for Industrial-Grade Liquid Storage

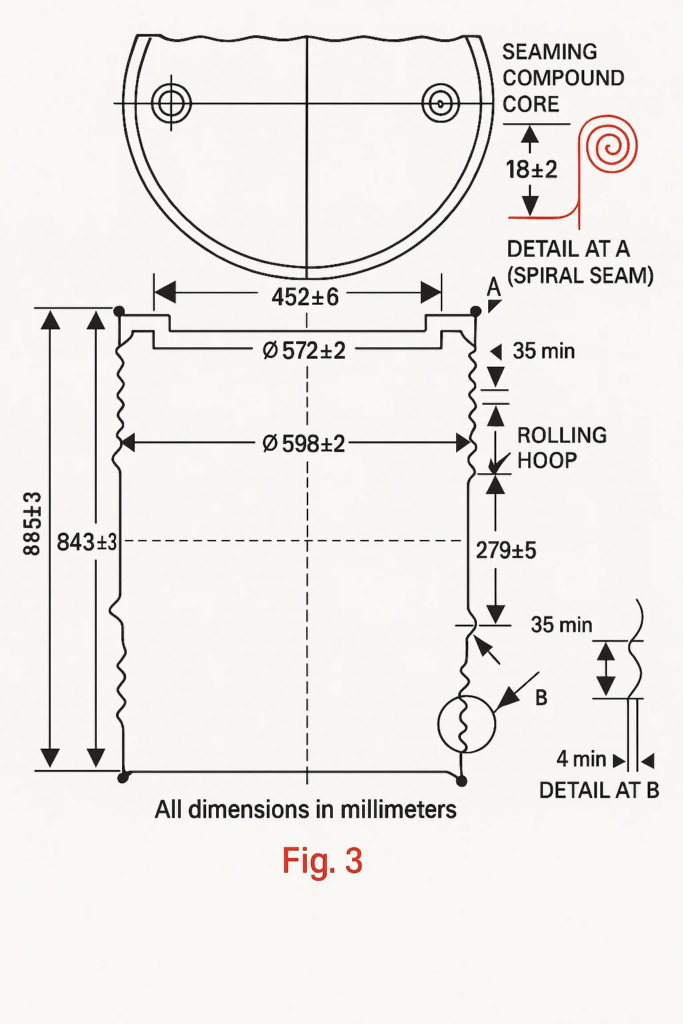

Our Triple Seam Tight-Head Steel Drums are crafted to meet the demanding requirements of industries that handle hazardous or high-value liquid materials. Designed and manufactured in accordance with IS 1783 (Part 2) – 1988 Type 2, these drums feature a seven-layer spiral seam construction with a 1.0 mm thick cold-rolled steel body and ends — offering a secure and durable packaging solution for chemicals, solvents, and export-grade fluids.

Key Features

Capacities Available

210 liters & 235 liters

Construction Material

1.0 mm cold-rolled steel (CRCA)

Seam Structure

Spiral triple seam rolled in 7 layers

Seaming Compound

Flexible and chemical-resistant core, preventing leaks and corrosion

Rolling Hoops

Reinforced mid-section for enhanced structural rigidity during handling and transport

Compliance

Manufactured under IS 1783 (Part 2) – 1988 Type 2 guidelines

Application Suitability

Storing and transporting various chemicals safely.

Chemicals & Petrochemicals

For acids, solvents, and corrosive fluids

Paints & Coatings

Safe containment for high-viscosity liquid paints and industrial coatings

Pharmaceuticals

Liquid intermediates and API handling

Oil & Lubricants

Transmission fluids, greases, and base oils

Agro-Chemicals

Fertilizers and plant protection liquids

Customization Options

Color Customization

Align drum colors with your branding requirements.

Epoxy Coating

Optional internal epoxy coating for enhanced protection against corrosion and contamination.

Markings

Custom stenciling and labeling as per client specifications.

Safety and Handling

Leakage Testing

Each drum undergoes rigorous leakage testing at 0.5 Kg/Cm² air pressure, adhering to IS:13997 standards.

Gasket Options

Equipped with flat, circular, or C-type gaskets made from rubber or EPDM, ensuring a secure seal.

UN Certification

Available for air and sea shipment, meeting international transport regulations.

Environmental Responsibility

Our drums are designed with sustainability in mind:

Reusable

Built for multiple uses, reducing environmental impact.

Recyclable

Made from materials that can be recycled, promoting eco-friendly practices.

Additional Information

NOTE – For more accurate insights, related products, and downloadable resources, check out the links provided. Here, you’ll find everything you need to make an informed decision.

Frequently Asked Questions (FAQs) ❓

What is a Triple Seam Tight-Head Steel Drum?

A Triple Seam Tight-Head Steel Drum is a closed-top drum where both the top and bottom ends are mechanically joined to the body using a seven-layer spiral seam process. This creates a secure, leak-proof seal suitable for storing and transporting liquids and hazardous materials.

What standards do your drums comply with?

Our drums are manufactured according to IS 1783 (Part 2) – 1988 Type 2, which ensures quality in seam construction, material strength, and overall leak resistance.

What capacities are available for these drums?

We offer Triple Seam Tight-Head Drums in 210-liter and 235-liter capacities to suit different industrial requirements.

What is the thickness of the steel used?

These drums are constructed using 1.0 mm thick cold-rolled steel for both the body and ends, providing excellent durability and structural integrity.

Are the drums leak-proof?

Yes. Each drum undergoes leakage testing at 0.5 Kg/Cm² air pressure, in compliance with IS:13997 standards. The seams are sealed with a resistant seaming compound to prevent leaks even under pressure.

Can the drums be coated internally?

Yes, we offer epoxy coating as an optional add-on for clients requiring protection against corrosion or for food-grade applications.

Are these drums suitable for international shipping?

Absolutely. On request, our drums can be provided with UN certification, making them compliant with air and sea freight regulations for hazardous or sensitive liquids.

Can I customize the drum with my brand color and logo?

Yes. We provide color customization, labeling, and branding options to align with your packaging requirements.

What’s the difference between a tight-head drum and an open-top drum?

A tight-head drum has a permanently sealed top, ideal for liquids and leak-sensitive materials. An open-top drum has a removable lid, better suited for solids, pastes, or semi-solids.

Other Products

Epoxy Coated Heavy Mild Steel Barrels

Protective epoxy-coated steel drums for food, pharma & chemicals.

GET Quote

GET Quote

Double Seam Tight-Head Steel Drums

Double Seam Tight-Head Steel Drums

IS 1783 (Part 2) Type 1

GET Quote